Industrial Sewing Machine Types and their Uses

Industrial Sewing Machines power today's

textile manufacturing, delivering the speed, precision, and durability that home machines simply cannot match. These specialized machines can handle everything from delicate silk to heavy leather, operating at speeds up to 5,000 stitches per minute while maintaining professional-grade accuracy.

Each machine has its own

job. Some make neat straight stitches. Some join thick layers of fabric with ease. Others are perfect for denim, leather, silk or upholstery. Choosing the right machine makes the work easier and the finish much better.

Every type has a special use, whether in making clothes, bags or furniture. Knowing these types helps us understand how everything we wear or use gets its perfect stitch.

Historical Evolution of Industrial Sewing Machines

Understanding the evolution of industrial

sewing technology helps appreciate modern machine capabilities. The history of industrial sewing machines started in 1790. It became the first step towards making clothes with machines instead of by hand. In 1863, Isaak Grobli invented the Schiffli embroidery machine. It joined the lock-stitch system with Jacquard punch cards, which allowed factories to produce embroidery on a much larger scale.

Then, in 1889, the Merrow Machine Company created the first overlock machine. This machine made neat and strong edges, which changed how garments were finished in factories. These early inventions shaped industrial sewing by making work faster, cleaner and easier to produce in bulk.

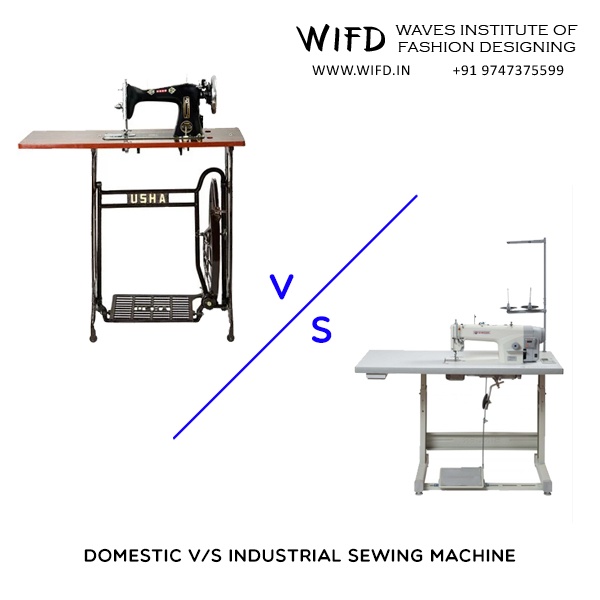

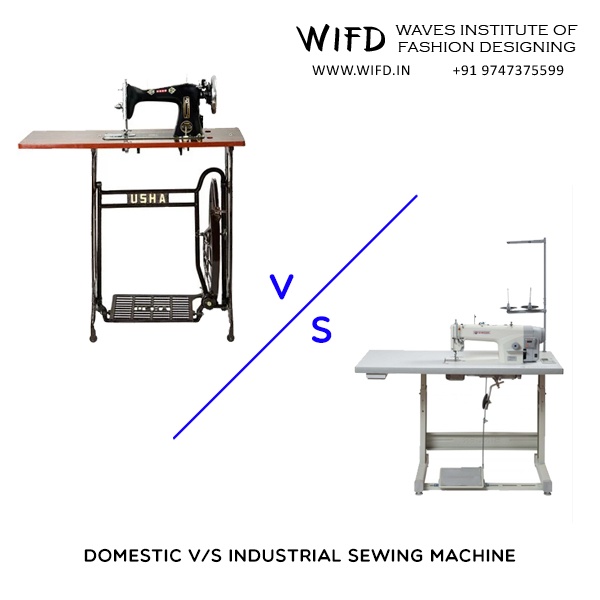

Industrial v/s Domestic Sewing Machines

Industrial sewing machines may look like bigger versions of home machines, but they work in a very different way. The first change is in their build. They use strong metal frames and solid parts that keep them steady. They don't shake much and can run for hours without trouble. Speed is another clear difference. A home machine works slowly and handles small tasks. Industrial machines run much faster and make hundreds of stitches in a minute. This speed is important when people need to sew in large numbers.

Power also sets them apart. Home machines use small motors that work well on thin fabrics like cotton. Industrial machines use stronger motors that can stitch thick cloth,

denim, or even leather without stopping. The design is not the same either. Home machines try to do many stitches in one unit. Industrial machines focus on one job. Some only make straight stitches, while others only do embroidery or overlock. This makes them more reliable for that single use.

Last comes durability. Home machines

suit light work once in a while. Industrial machines are made for daily use in factories. Their parts last longer and keep giving the same quality even after years of heavy work.

| Feature | Domestic Sewing Machine | Industrial Sewing Machine |

|---|

| Build | Light frame, less stable | Strong metal frame, very steady |

| Speed | Slower, for small tasks | Very fast, hundreds of stitches per minute |

| Power | Small motor for thin fabrics | Strong motor for thick and heavy fabrics |

| Design | Multi-purpose in one unit | Specialised for one type of stitch |

| Durability | Best for light, occasional use | Made for daily, long-hour work |

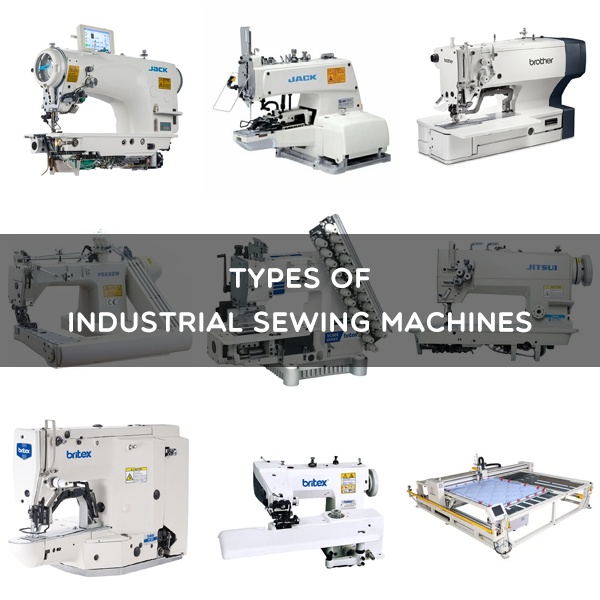

Types of Industrial Sewing Machines

Single Needle Lock Stitch Machine

The Single Needle Lock Stitch Machine is the most versatile industrial sewing machine, accounting for over 60% of all garment construction operations. Lock stitch machines create the strongest seam type by interlocking upper and lower threads through the fabric layers. On both sides of the fabric, the stitches look the same. Lock stitches are formed with one needle thread and one bobbin thread. It is used for joining two or more multiple fabric pieces together and can be used to sew light weight, medium weight and heavy materials.

Overlock Sewing Machine

Overlock machines (also called sergers) are essential for professional edge finishing. Available in 3-thread, 4-thread, and 5-thread configurations, they simultaneously cut, sew, and finish fabric edges in one operation. These machines are crucial for

knitted garments where fabric stretch must be maintained.

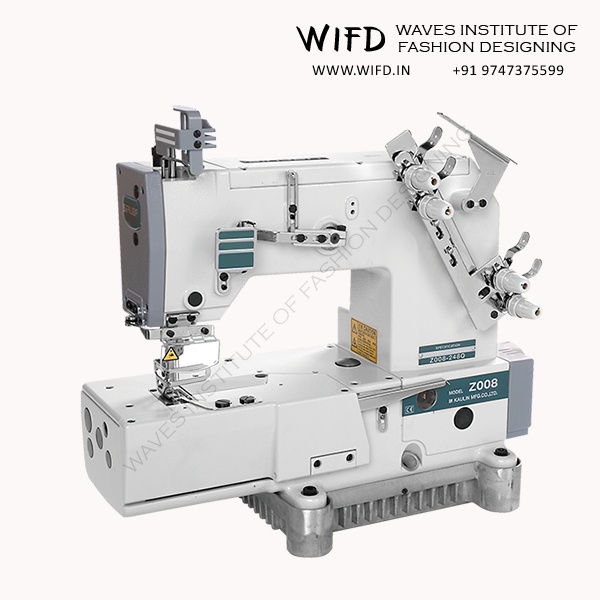

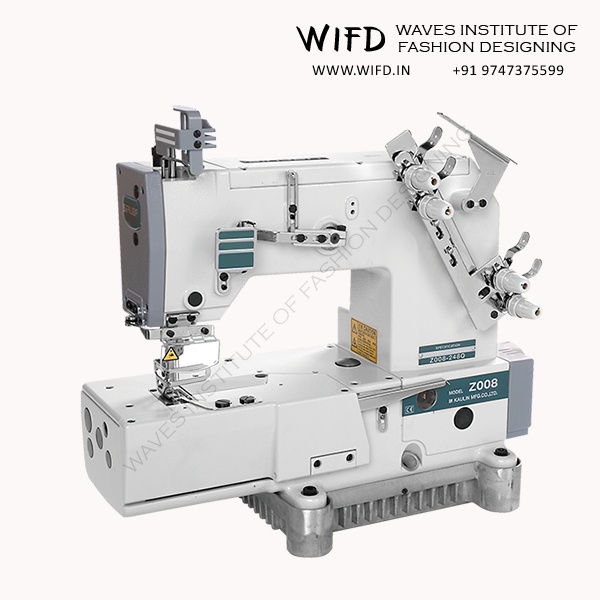

Cover Stitch / Flat Lock Sewing Machine

Cover Stitch Sewing Machine is also known as Flat Lock Sewing Machine. The primary objective of this type of machine is to build professional looking hems in apparels. It is a specialised machine for hemming, binding, top

stitching and decorative effects. It also includes a dual function to cover raw edges of the fabric and retains fabric stretchability.

Chain Stitch Machine

Creates a chain stitch useful for stretched fabrics and for binding & decorative effects. Chainstitch is continuously formed with a single thread and by a

blind looper which eliminates the need for a bobbin thread refilling.

Blind Stitch Machine

Blind Stitch Machine makes an invisible hem stitch joining two pieces of fabric. This machine is very fast and efficient and with the help of a special

presser foot it can also create a blind hem.

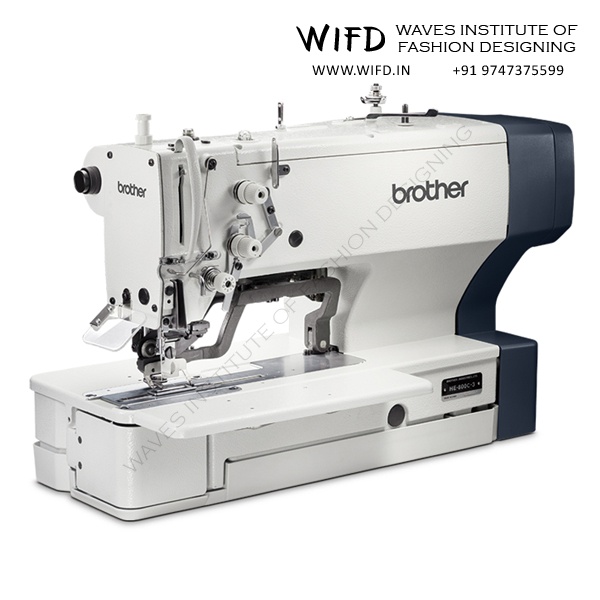

Bar Tack Machine

There are certain areas in a garment that need reinforcing. Bar tack machines are specialised in sewing the little stitches on the top edge of pockets or on the loops for a belt and other areas that need reinforcing.

Feed-off the Arm

For making flat-fell seam, this machine is used. Two needle threads form the chain stitch. This machine is used for sewing side seams of the shirt, under arms and for sewing

jeans' inseams.

Zig-Zag Machine

This type of sewing machine does zig zag stitches and is used mainly to attach elastic in bra and under wear production. Zig Zag stitch is one of the most durable stitches and a triple zig zag stitch is considered to be the strongest stitch.

Button Attaching Machine

This is a special machine used only for stitching buttons in a garment. Different sizes of buttons can be attached in the same machine by changing the settings.

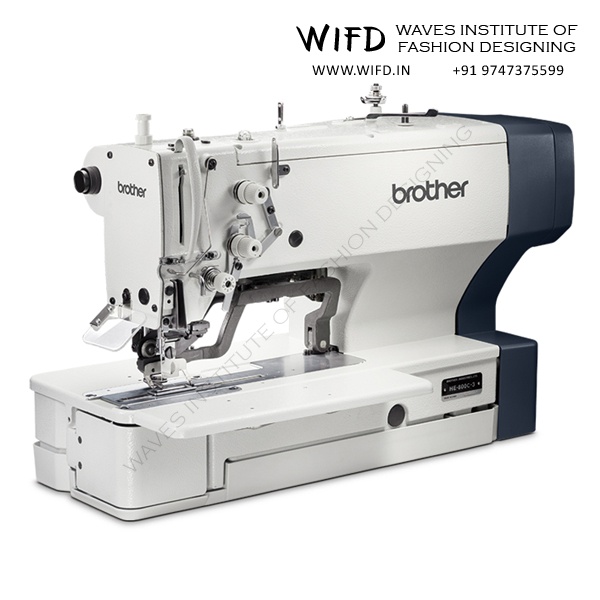

Button Hole Machine

Buttonholes are holes in the garment which allow buttons to pass through them and the raw edges of the button hole are finished by stitching. It secures one piece of the fabric to another.

Multi Needle Chain Stitch Machine

Multi Needle Chain Stitch Machine is used for pin-tuck and smocking operations.

Double Needle Lock Stitch Machine

Double Needle Lock Stitch Machine has twin needles. This machine is used for sewing two parallel lines at the same time on a garment. By this stitching, time can be considerably reduced.

Embroidery Machines

This machine will have access to built-in designs and a memory facility to store designs. The USB port on this machine enables the embroider to access other designs and import them into the memory of the machine.

Quilting Machine

This machine is used to make large quilts. It has a longer arm allowing greater volume of fabric to pass through the machine. As the fabrics are held in place, the feed of the machine ensures steady and even sewing.

Post Bed Machine

Post bed machines feature a vertical post instead of a flat bed, allowing operators to sew cylindrical items like sleeves, cuffs, and small bags. Essential for leather goods,

shoes, and curved seam construction.

Cylinder Bed Machine

Cylinder bed machines have a narrow, cylindrical work surface perfect for sewing sleeves, cuffs, and small circumference items. The cylinder design allows fabric to move freely around the sewing area.

Walking Foot Machine

Walking foot machines use synchronized feed mechanisms above and below the fabric, preventing shifting and ensuring even feeding of multiple layers or heavy materials like leather, canvas, and upholstery.

Blind Hem Machine

Specialized for creating invisible hems on garments, particularly pants and

skirts. Uses a curved needle to catch only a few threads of the fabric surface.

Snap Button Machine

Automated machines for attaching snap buttons, press studs, and similar fasteners. Features pneumatic or mechanical pressing mechanisms for consistent attachment.

Picoting Machine

Creates decorative picot edges with small loops or scallops. Popular in

lingerie, handkerchiefs, and decorative home textiles.

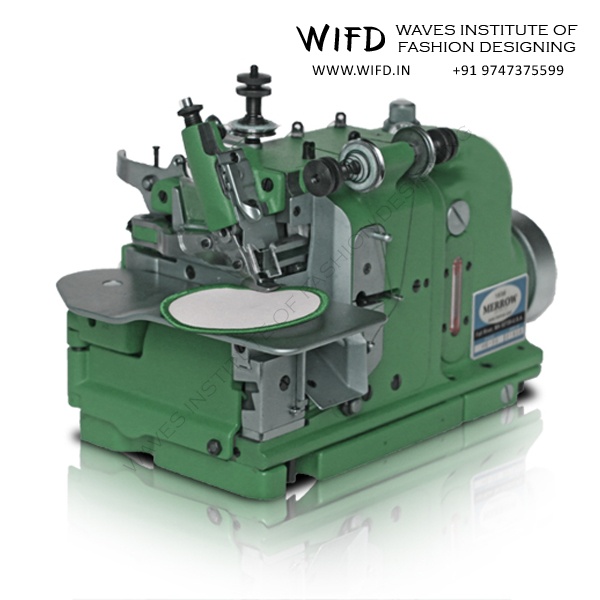

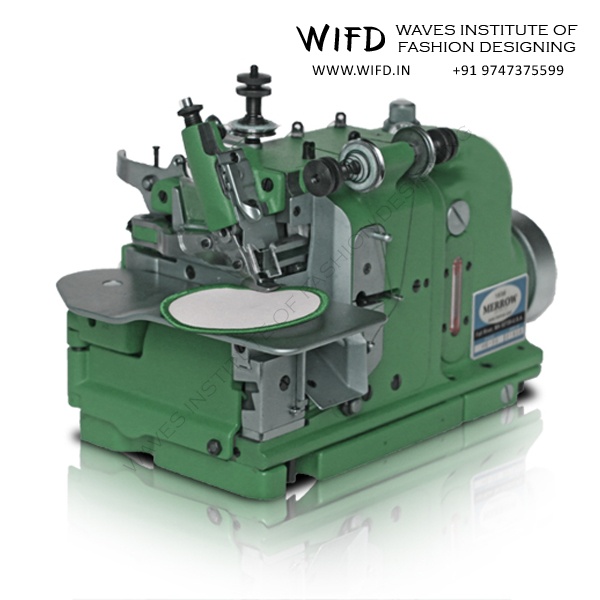

Merrow Machine

Specialized overlock machine that creates a knit edge stitch. Produces a strong, neat edge finish particularly popular in

activewear and flag manufacturing.

Basting Machine

Creates temporary stitches to hold fabric pieces in position before permanent sewing. Often uses easily removable thread or long loose stitches.

Smocking Machine

Creates gathered, decorative stitching patterns often seen in children's

clothing and traditional garments. Uses multiple needles to create uniform gathering patterns.

Pocket Setting Machine

Automated machine for precise pocket attachment including welted pockets, patch pockets, and in-seam pockets. Ensures consistent placement and professional finishing.

Innovations: Automation in Industrial Sewing

Industrial

sewing machines have changed a lot in recent years. Automation makes them quicker, more accurate, and easier to use. Many machines now have digital controls to set stitch type, tension, and speed with a simple press. This keeps the stitching neat and the results the same every time. Automatic thread cutters save time by trimming the thread on their own. Some machines also lift the presser foot automatically, so workers can move fabric without extra effort. Pattern sewing machines can store designs and repeat them again with the same finish, which helps in bulk production.

Sensors and settings add more support. They guide the needle, check fabric movement, and stop the machine if there is a

problem. This makes the work safer and reduces fabric waste. Automation also reduces strain on workers. With less manual effort, they feel less tired and can focus better on quality. Factories can produce more pieces in less time while keeping the work comfortable.

Overall, automation has made industrial sewing more efficient, safe, and reliable.

How to Choose the Right Machine

The best sewing machine depends on what you plan to sew. For stretchy fabrics like knits, an overlock or interlock machine works best. Thick fabrics such as leather need a lockstitch machine. For soft or delicate cloth, an embroidery machine gives neat results without damage. Stitch type also matters. Use a lockstitch for strong seams, an overlock for clean edges, and an embroidery machine for decoration.

Think about how much you need to produce. Big factories choose single-purpose machines that run fast. Small workshops often prefer multipurpose machines that can do more than one job. Skill level makes a difference too. Programmable machines can handle tough work and make sewing easier for less experienced users.

Budget is the final point. Industrial machines cost more, but they last longer and stay reliable with heavy use. Always choose a machine that balances your needs with your spending.

Keeping your Machine in Good Condition

Industrial sewing machines work hard every day, so they need regular care to stay in good shape. Clean the feed dogs and bobbin area daily to remove dust and thread pieces. This keeps the fabric moving smoothly and stops small problems from turning into big ones. Oil the machine on time. Put a few drops in the marked spots as shown in the guide. A dry machine wears out quickly, while a well-oiled one runs quietly and lasts longer.

Change needles often. Old or bent needles damage fabric and make uneven stitches. A new needle always gives neat and strong stitching. Check the thread tension now and then. If it is too loose or too tight, the stitches will not look right. Adjust it slightly until the stitches are even on both sides.

These small steps keep the machine running well and help it last for many years. Regular care also saves repair costs and keeps work moving without delay.

Automated Waistband Sewing in Modern Apparel Production

In 2026, a new sewing system made waistband stitching quicker and more accurate. The machine used sensors to check how much the waistband stretched. Rolling feeds kept the fabric moving evenly, so every stitch stayed neat. It also had a differential system designed for elastic. This allowed the waistband to stretch without pulling the fabric out of shape. Each part of the machine worked together, so the stitch looked clean even at high speed.

Factories want speed, accuracy, and less manual work. With this system, one worker could do jobs that once needed several skilled hands. The machine handled the difficult steps on its own. This waistband system showed how sewing machines now use sensors and automation to meet the fast needs of today's clothing

industry.

Top 5 Industrial Machines to Buy in 2026

Leading industrial sewing machine manufacturers offer proven reliability and global service support, essential

factors for production environments. Choosing one, completely depends upon your usage. Before you select your next machine, make sure that you can avail services nearby to your location. Here are few of the best brands and models of 2026.

- Juki DDL-8700 Straight Stitch (Servo) - Energy-efficient servo motor, ideal for medium-weight fabrics.

- Brother PQ1500SL High-Speed Industrial Machine - High-speed quilting and straight stitch applications.

- Juki DDL-5550 Industrial Straight Stitch Sewing Machine

- Singer 191D-30 - Heavy-duty construction for leather and thick materials.

- Juki LU-2810-7 Walking Foot Industrial Machine

Industrial sewing machines keep changing with time. They are no longer just about speed and strength. Today, many come with smart controls, automation, and features that make stitching faster and more accurate. Sustainability is now very important. Brands look for machines that work well with

eco-friendly fabrics and support cleaner ways of making clothes. Customisation also matters because designers often need machines that handle small batches and unique designs without slowing down.

For students, designers, or anyone in garment making, understanding these machines is a must. Picking the right one saves money, improves quality, and makes work easier. The

future will favour those who learn quickly and use the right tools with skill.

FAQ about Industrial Sewing Machine

1. Can I use an industrial sewing machine with normal home electricity?

Yes. Most machines work on 220-240V single-phase power, the same as Indian homes. Big embroidery or quilting machines may need three-phase.

2. Do they use a lot of electricity?

No. Modern machines with servo motors use less power, usually 400-750 watts. They save a lot compared to old clutch motors.

3. Can I run a machine on an inverter?

Yes, but use a pure sine-wave inverter. For one machine, a 1.5-2 kVA inverter is safe. Use good wiring, proper earthing, and a stabiliser if voltage fluctuates.

4. Do all machines need compressed air?

No. Only machines with pneumatic parts like auto foot lifts need it. A small compressor is enough for one or two machines.

5. Which needles are used in lockstitch machines?

Most use DBx1 needles (sizes 65-110). Heavy-duty ones often use DPx5. Always check the manual.

6. Which oil should I use?

Use light sewing machine oil. Most machines need ISO VG 7-22 grade oil. Brands like Mobil or Juki Defrix are common.

7. How often should I service the machine?

Clean lint and check oil daily. Check needles, tension and belts weekly. Call a technician every 6-12 months for a full check-up.

8. What is the price of machines in India?

- Basic lockstitch: Rs.20,000 - 40,000/-

- Overlock: Rs.25,000 - 55,000/-

- Heavy-duty walking foot: Rs.45,000 - 90,000/-

- Coverstitch: Rs.45,000 - 80,000/-

- Auto functions: Rs.80,000 - 1,80,000/-

- Embroidery (Multi-needle): Rs.5,00,000 - 15,00,000/-

9. What plug do I need?

Most machines run on a normal 6A-16A plug, but use a separate circuit with earthing for safety.

10. Are there government schemes to buy machines?

Yes. PM Vishwakarma gives training, a Rs.15,000 toolkit and easy loans. PMEGP and CGTMSE also support small units. States have their own schemes too.

11. Which is better: direct-drive or belt-drive?

Direct-drive is quieter, uses less power and starts smoothly. Belt-drive with clutch motors is cheaper but noisy.

12. How much should I budget for maintenance?

Keep 1-3% of the machine's cost per year for oil, parts and servicing.

13. What should I check when buying a second-hand machine?

Check for noise, wear on hook and feed, loose needle bar, and test stitches on your own fabric.

14. Do machines need dust control?

Yes. Dust and lint affect performance. Clean daily with a vacuum or brush. Good lighting also helps.

15. Do I need training to use the machine?

Yes. Ask the dealer for training on threading, oiling and safety. Many brands give guides and videos.

CONTACT USWaves Institute of Fashion Designing,

CONTACT USWaves Institute of Fashion Designing,