| Hook Type | Movement | Common Use |

|---|---|---|

| Rotary hook | Moves in a full circle | Industrial machines and modern domestic machines |

| Oscillating hook | Moves back and forth | Traditional domestic machines |

| Drop Feed | The standard mechanism where feed dogs push fabric while the needle is out. |

| Differential Feed | Uses two sets of feed dogs to stretch or compress fabric, preventing puckering in knits. |

| Needle Feed | The needle itself helps move the fabric, preventing layers from shifting. |

| Puller Feed | Uses rollers to grip and pull heavy materials like leather or tents. |

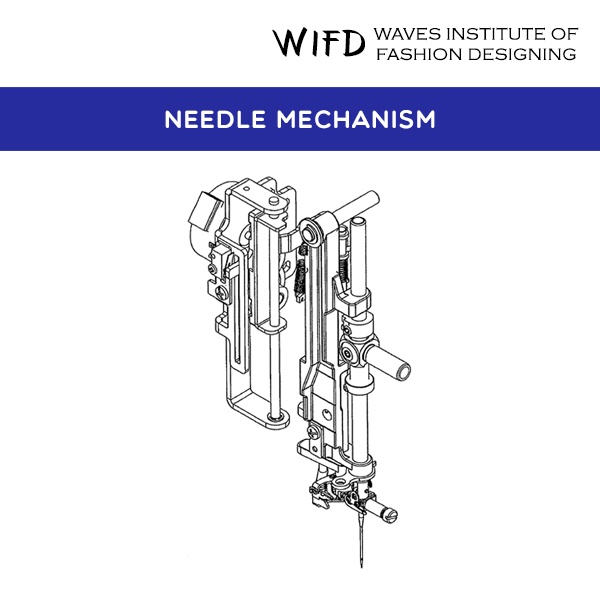

| Shank | The flat top part that fits into the machine. It keeps the needle aligned correctly. |

| Shaft | The long body that supports the needle as it moves through the fabric. |

| Groove | The long channel that carries the upper thread smoothly down to the fabric. |

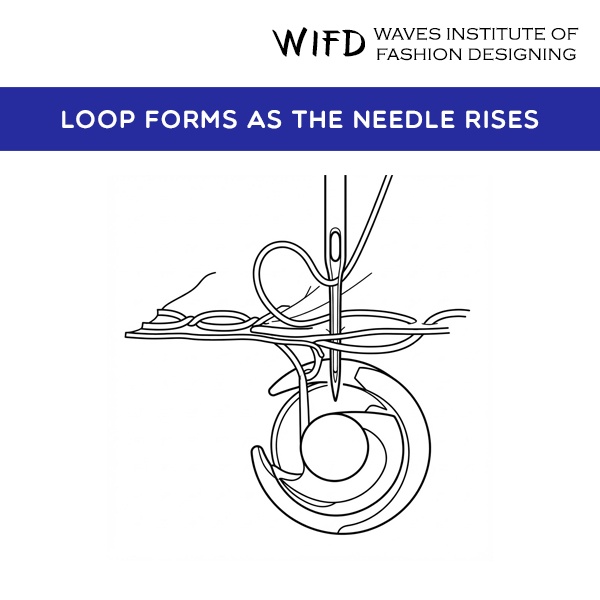

| Scarf | The small cut-out above the eye. It helps the hook catch the thread loop. |

| Eye | The hole where the thread passes through. A larger eye suits thicker thread. |

| Point | The tip that pierces the fabric. The point shape decides how the needle enters the fabric. |

| Fabric Type | Needle Size |

|---|---|

| Sheer fabrics, Chiffon | 60/8 |

| Light cotton, Lining | 70/10 |

| Medium cotton, Poplin | 80/12 |

| Heavy cotton, Twill | 90/14 |

| Denim, Canvas | 100/16 to 110/18 |

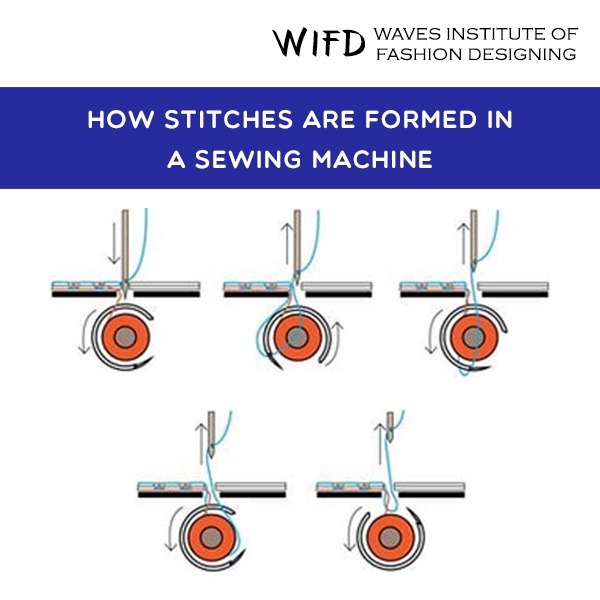

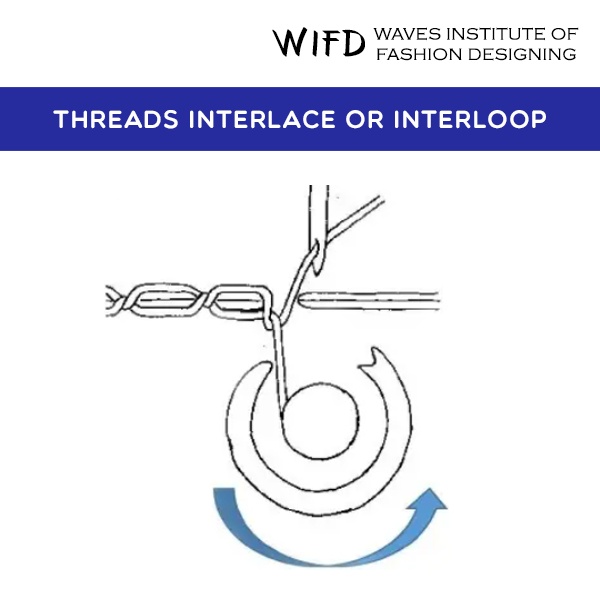

A sewing machine forms stitches when the needle carries the upper thread through the fabric and links it with the lower thread from the bobbin or looper. The machine then tightens the threads to create a secure stitch.

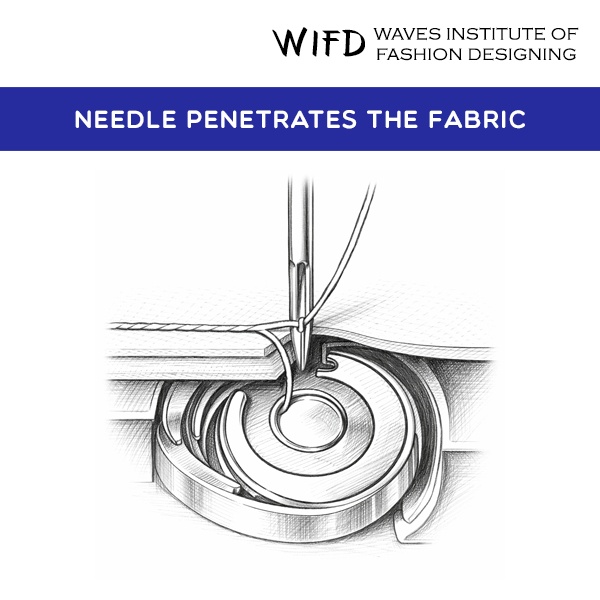

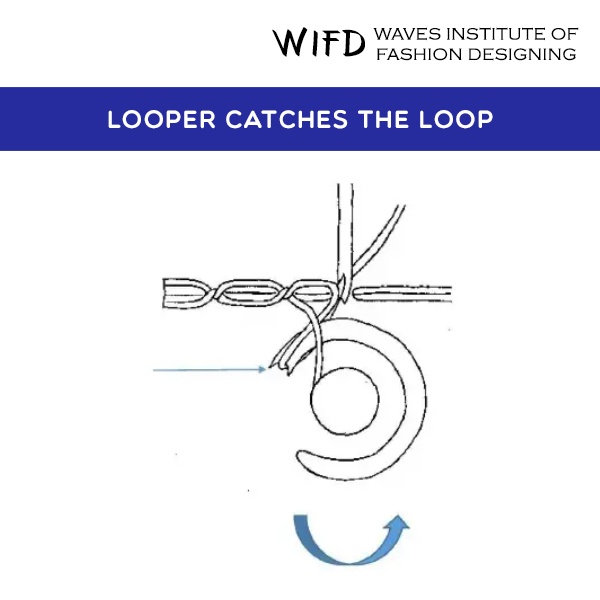

The needle pushes the upper thread through the fabric and creates a loop. This loop allows the hook or looper to catch the thread and start forming the stitch.

The bobbin holds the lower thread. It works with the upper thread to lock or loop the stitch, which gives strength and stability to the seam.

The take-up lever pulls the upper thread back after the threads join. This action tightens the stitch and sets it neatly inside the fabric.

Feed dogs move the fabric forward after each stitch. This steady movement keeps stitch length even and prepares the fabric for the next stitch.

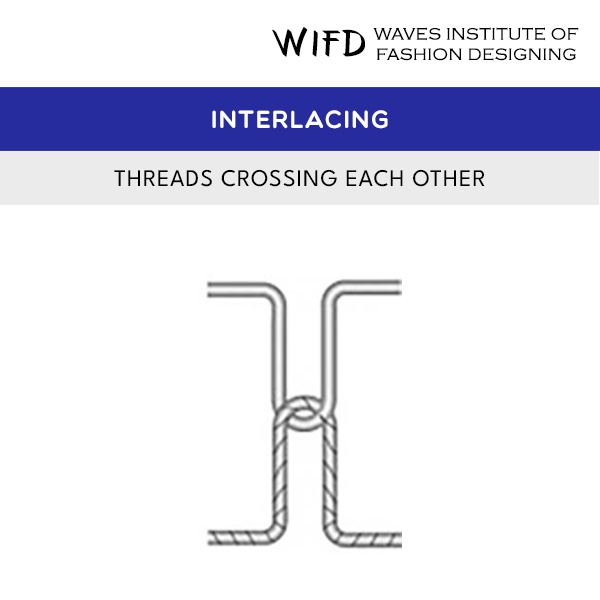

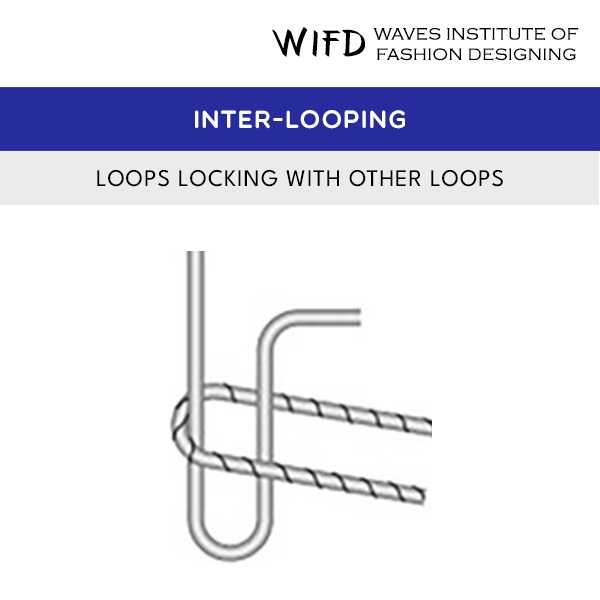

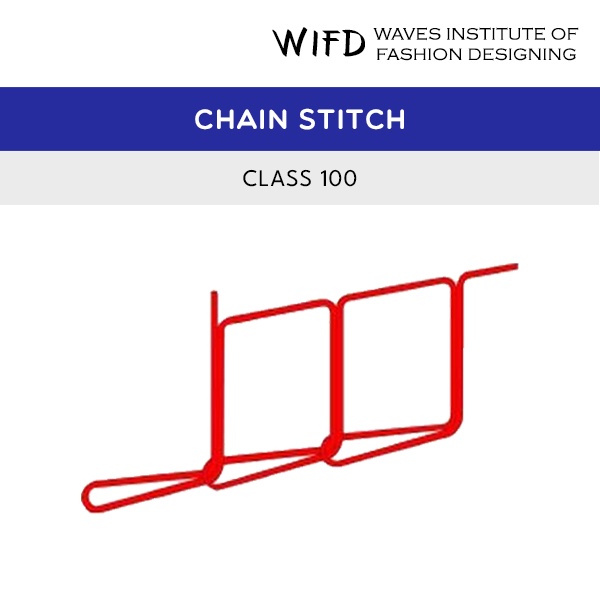

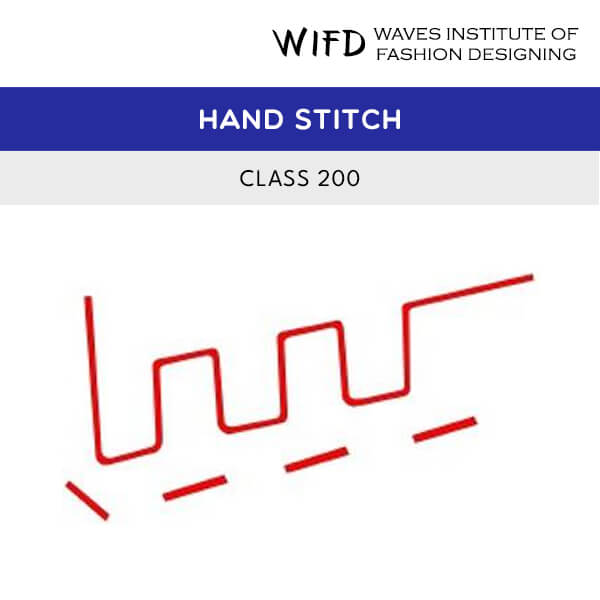

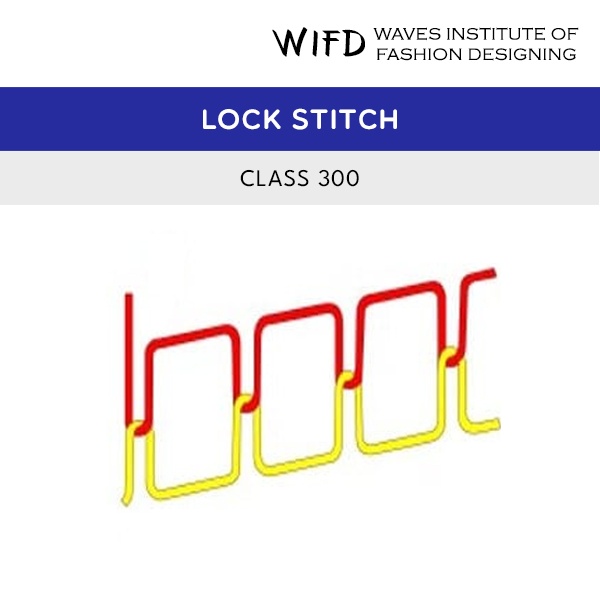

A lockstitch joins the upper and lower threads in the centre of the fabric, creating a strong and secure seam. A chain stitch forms loops on the underside and offers more stretch but less strength.

Correct thread tension keeps stitches balanced and smooth. Poor tension causes loose loops, puckering or uneven stitches.

The machine tightens each stitch when the take-up lever pulls the upper thread upward. This action locks the threads together before the fabric moves forward.

Skipped stitches usually occur due to a blunt needle, wrong needle size, incorrect threading or poor timing between the needle and hook.

Understanding stitch formation helps you choose the right stitch, improve sewing quality and solve stitching problems with confidence.

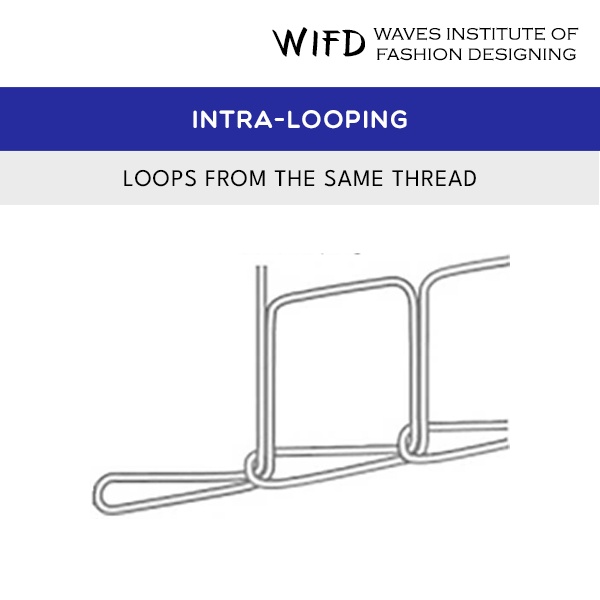

A bobbin holds a separate lower thread and creates lockstitches. A looper forms stitches by creating thread loops instead of using a bobbin, which allows more stretch in the seam.

Use a stretch needle or ball point needle for stretchy fabrics. These needles slide between fabric fibres and reduce skipped stitches.

A walking foot machine feeds the top and bottom fabric layers evenly. This balanced movement prevents shifting and creates even stitches on thick quilt layers.

Ball point needles suit knitted fabrics and gently push fibres aside. Stretch needles work better on highly elastic fabrics and prevent skipped stitches more effectively.

| ABOUT THIS ARTICLE | |

|---|---|

| Published On | 02 Jan 2026 |

| Updated On | 02 Jan 2026 |

| Author | Waves Institute of Fashion Designing |

| Publisher | Waves Institute of Fashion Designing |

| URL | https://articles.wifd.in/how-stitches-are-formed-sewing-machine |

CONTACT USWaves Institute of Fashion Designing,

CONTACT USWaves Institute of Fashion Designing,