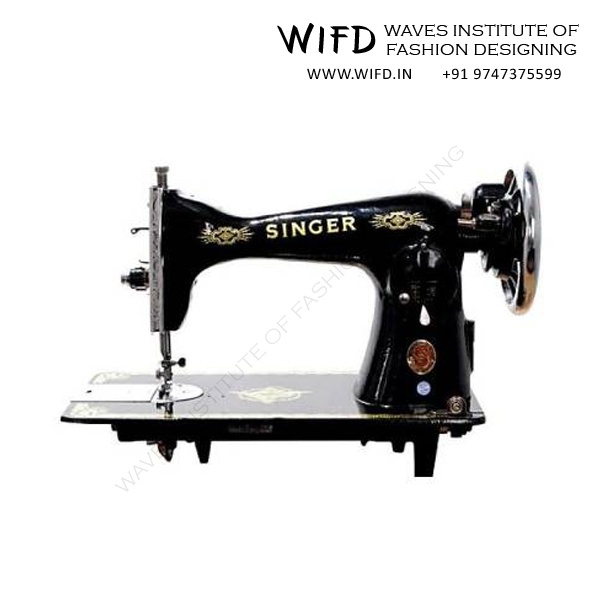

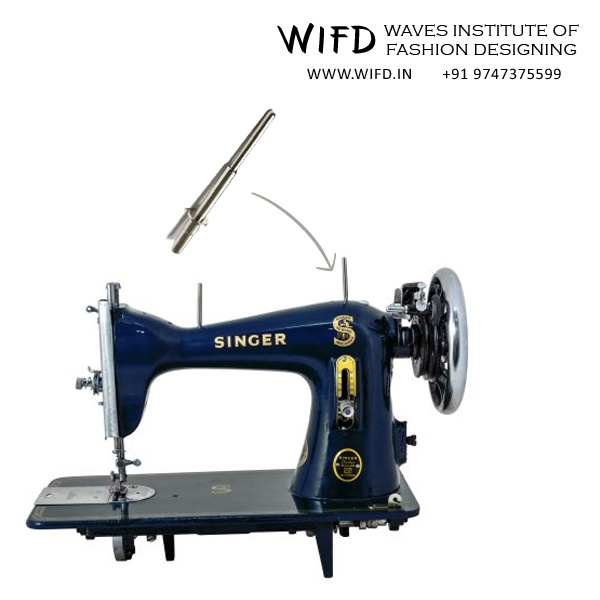

Head

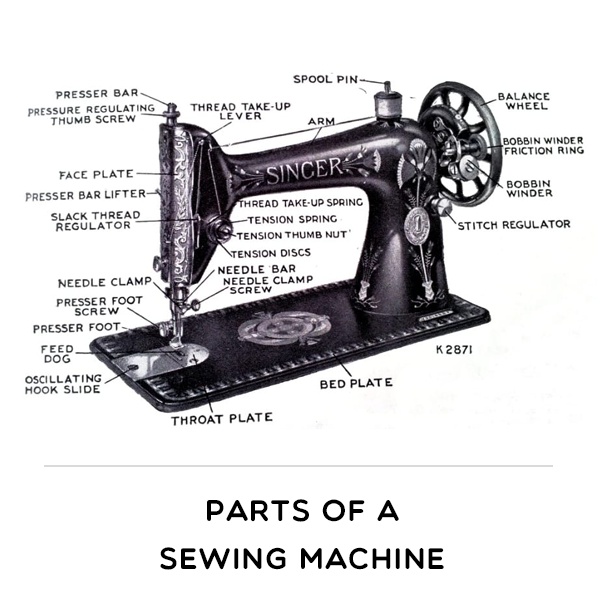

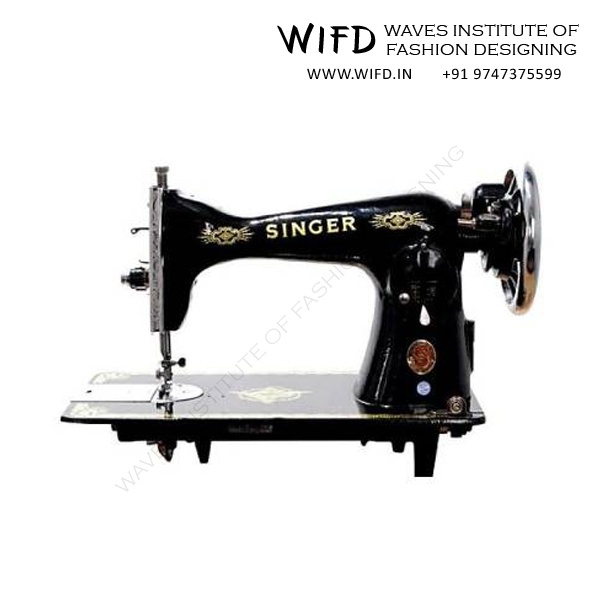

Head refers to the complete sewing machine excluding the stand or cabinet. It houses the main working mechanisms like the needle bar, presser bar, take-up lever and tension system. It controls stitch formation and thread movement during sewing. The head consists of two main parts: the arm and the bed.

Arm

The arm is the curved upper section that drives the needle and handles the upper thread.

Bed

The Bed is the flat portion of the head in a sewing machine under which is mounted the shuttle, feed and lower thread handling mechanism. It supports the fabric during sewing and holds important parts like the feed dog.

Balance Wheel / Hand Wheel

Balance Wheel, also known as Hand Wheel, is on the right side of the head driven by a belt or a handle. It raises and lowers the take-up lever which is used to move the needle up and down. Always turn the hand wheel towards you, even when reverse stitching.

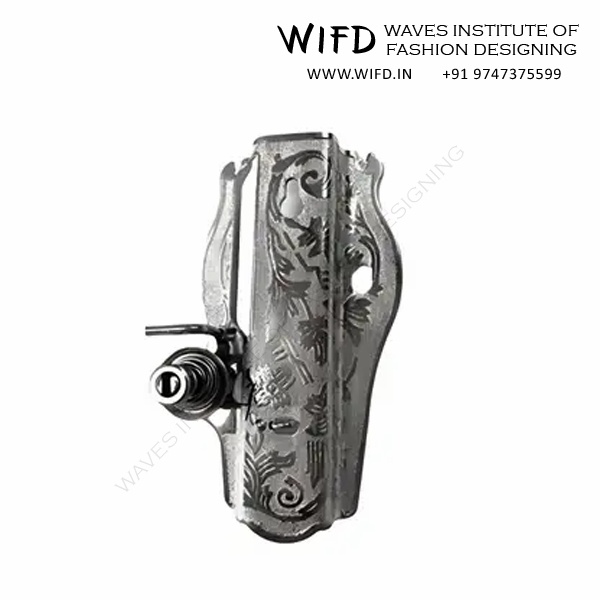

Face Plate

This plate sits on the left side and covers oiling points for the needle bar, presser foot bar and take-up lever. It protects internal moving parts and allows easy access for oiling, cleaning and maintenance.

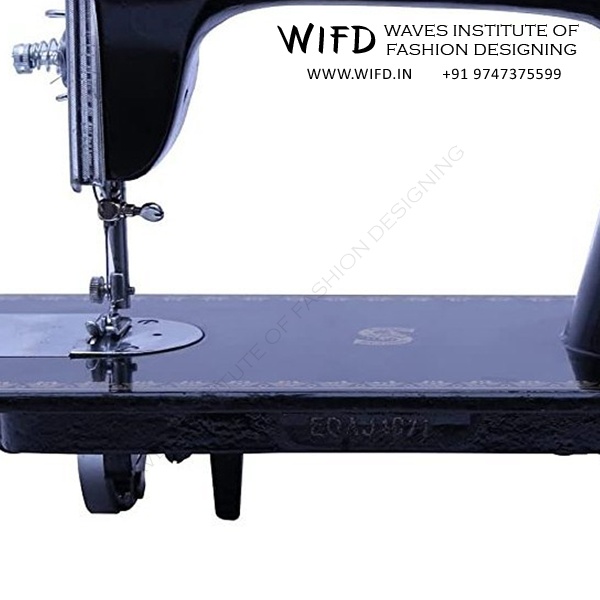

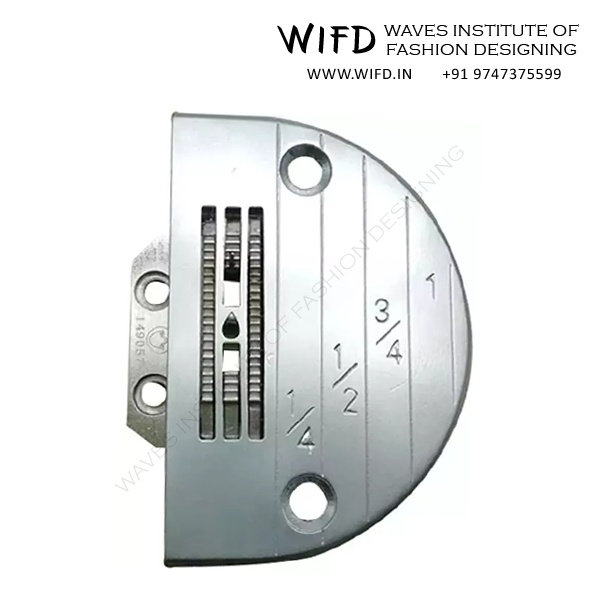

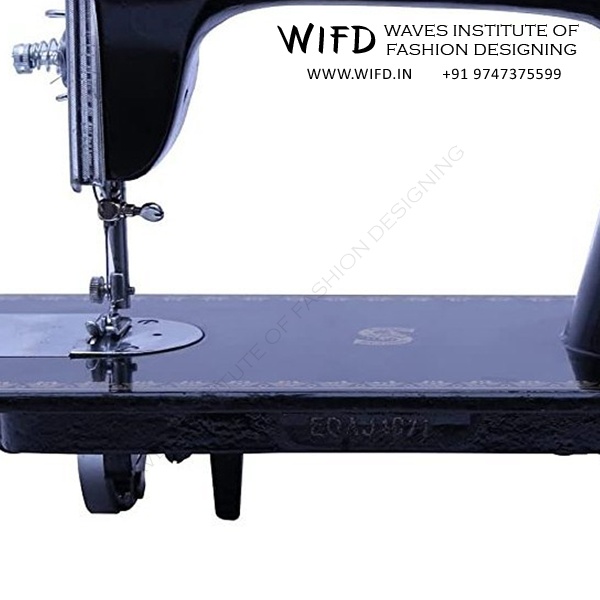

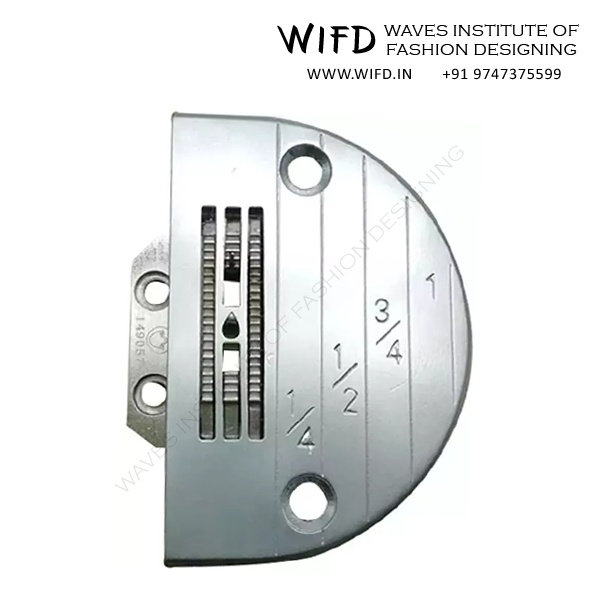

Throat Plate / Needle Plate

The throat plate (also called Needle Plate) is a semi-circular disc with a hole between the presser foot and bobbin case. The needle passes through this hole during stitching. It provides a level surface for fabric and includes seam allowance guides marked to the right of the presser foot. The plate can be detached manually to clean and remove pieces of thread caught inside.

Sliding Plate

The sliding plate covers the bobbin area on the bed. It slides open to allow easy access for inserting or removing the bobbin. Different machines use either a slide plate or hinged cover for bobbin access.

Presser Foot

The presser foot holds fabric flat against the throat plate to prevent slipping. Change presser feet for different tasks like zipping, buttonholes or hemming. Different types of presser foot are available for different functions such as zipper foot, button hole foot etc.

Presser Foot Lifter

This lever attaches to the presser bar above the presser foot. It raises and lowers the presser foot when you need to insert or remove fabric. Always lift it before removing fabric and lower it before stitching.

Feed Dog

The feed dog uses its metal teeth to move fabric forward and backward beneath the presser foot. The feed dog rises to advance fabric with each stitch. Press the pedal harder for faster movement.

Stitch Length Regulator

Marks on the lever show different stitch lengths. Use medium-length stitches for general sewing, shorter stitches for fine fabrics and longer stitches for heavy fabrics, basting or gathering.

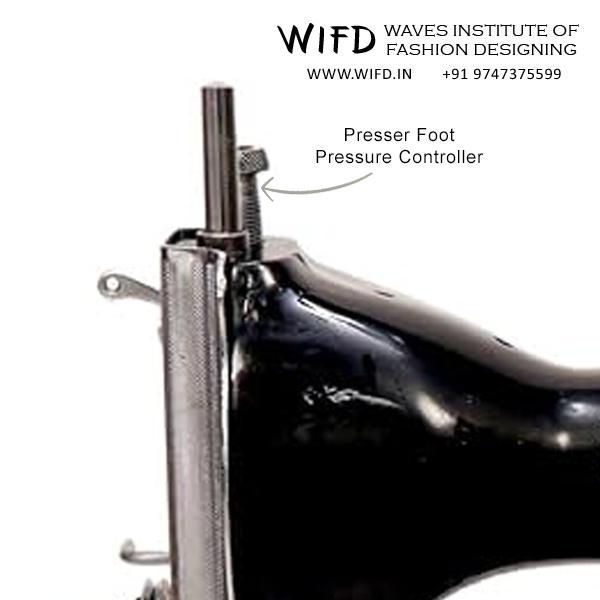

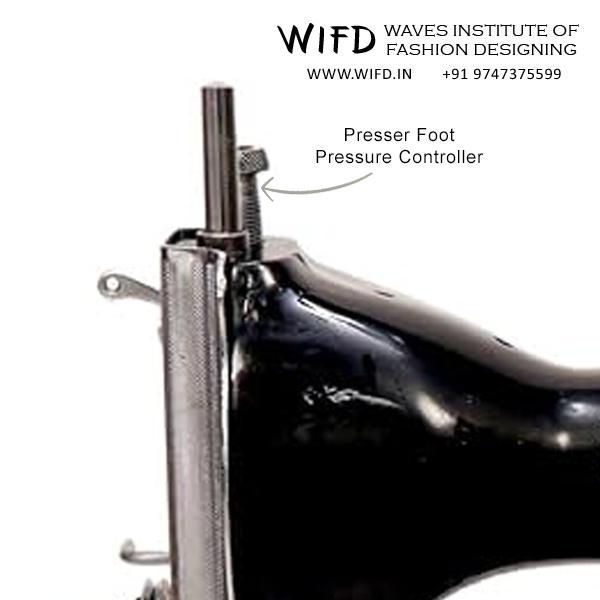

Presser Foot Pressure Controller

Presser Foot Pressure Controller adjusts the amount of pressure the presser foot applies to the fabric as it feeds the fabric beneath the needle. Decrease pressure for lightweight fabrics and increase pressure for heavy fabrics.

Reverse Sewing Lever

This lever sits near the stitch length control on most machines. It allows backward stitching to lock seams securely at the beginning or end. Many basic domestic machines lack this feature.

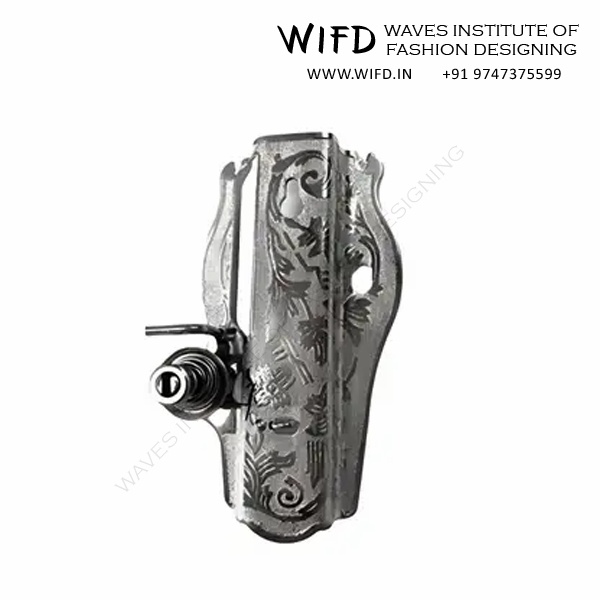

Pressure Bar Spring

This

spring sits inside the head and creates downward pressure on the presser foot bar. It provides pressure to the presser foot bar and helps maintain consistent fabric control during stitching.

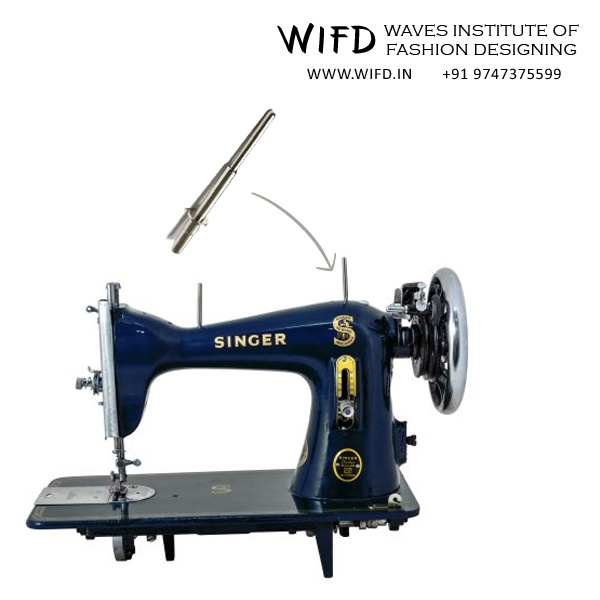

Spool Pin

This upright metal rod on top of the arm holds the thread spool. It keeps the thread spool stable during sewing. Some machines include multiple spool pins for decorative or twin needle work. It can either be vertical or horizontal. The horizontal ones provide smoother thread feed.

Tension Regulator

This mechanism on the face plate controls upper thread tension, which directly affects stitch quality. Two discs squeeze together with the thread passing between them. A spring and dial adjust how tightly the discs squeeze the thread. Balance both upper and bobbin tension for even stitches. Too much tension causes puckering and breaks. Too little makes loose, weak stitches. Turn the dial anti-clockwise to decrease and clockwise to increase the tension of the upper thread.

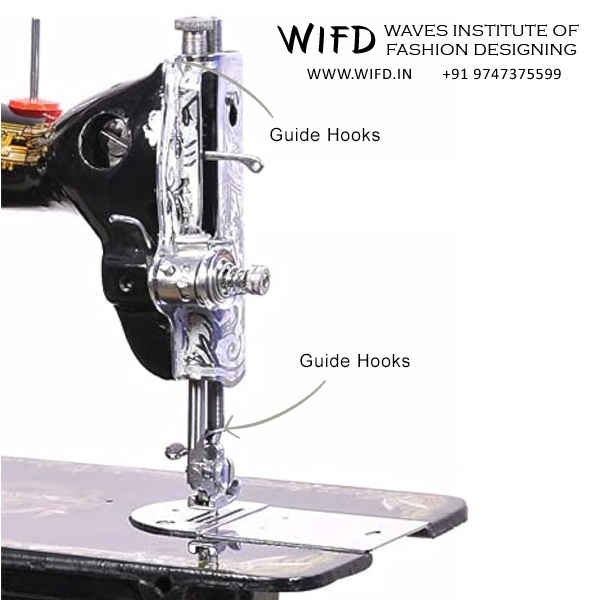

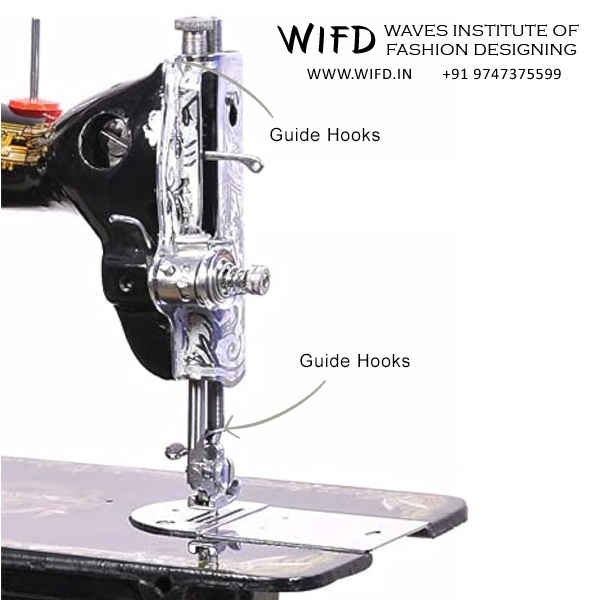

Thread Guides / Guide Hooks

Thread guides are multiple loops, discs or metal shapes positioned from the spool pin down to the needle. Thread passes through these guides without tangling, helping maintain proper tension.

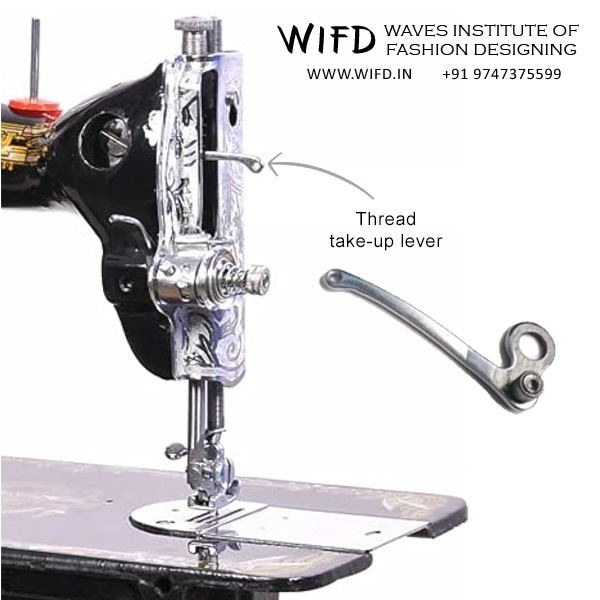

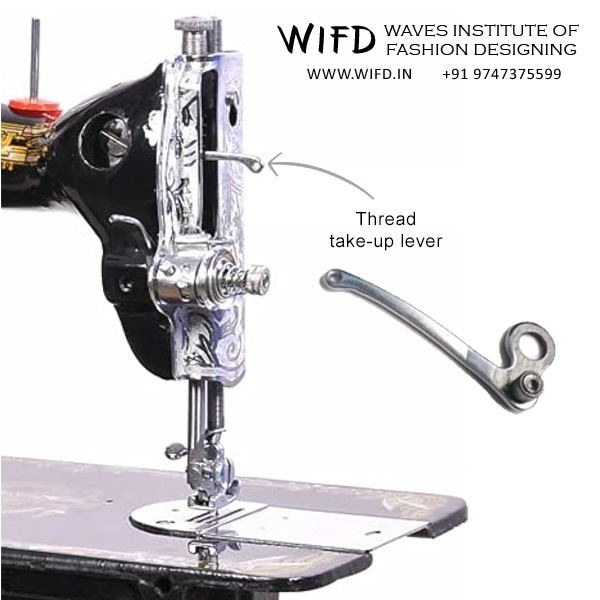

Thread Take-up Lever / Bar

This lever moves up and down above the tension regulator. A small hole at its end allows thread to pass through. This lever serves two key functions:

- To feed the thread to the needle.

- It releases thread as it drops and tightens the stitch as it rises.

Needle Bar

The needle bar holds and moves the needle up and down. A needle clamp screw on this bar holds the needle in place.

Needle

The needle is a precisely engineered metal shaft with a sharp point and a small eye for thread. Each needle has five parts: the shank, shaft, front groove, scarf and eye. One side of the Shank is flat and the other side is round. A groove on the round side protects the thread during stitching. The scarf is a cut-away section on the flat side near the point. Twin needles create parallel decorative lines. Needles are made of steel and may have chrome or titanium coating. They come in various sizes and types for different fabrics.

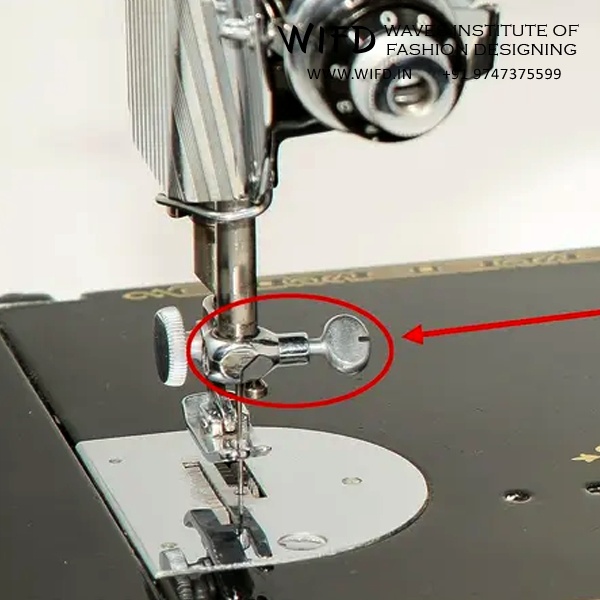

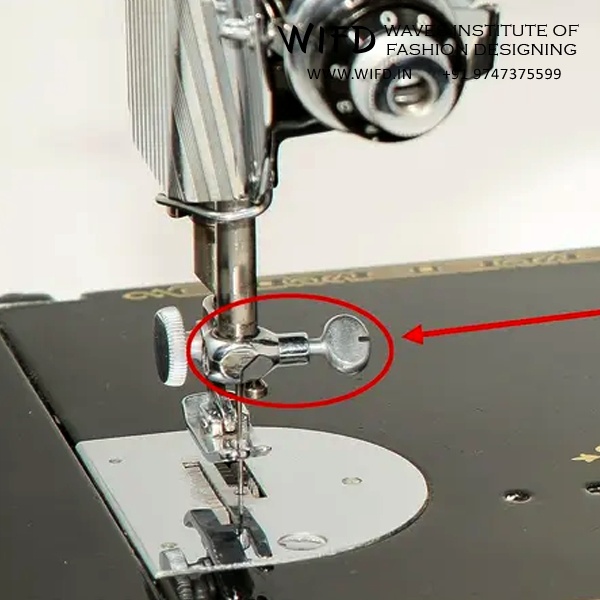

Needle Clamp

The needle clamp and its screw hold the needle firmly in place. Loosen this screw with a screwdriver to change needles, then tighten to secure.

Bobbin

The bobbin is a crucial part of every sewing machine. It is a small plastic or metal spool used for winding the thread. It supplies the lower thread during

stitch formation.

Bobbin Case

The bobbin case holds the bobbin and controls lower thread tension. Bobbin case design varies by machine. Some machines load bobbins from the front, others from the top. Some machines have built-in bobbin cases.

Rotatory Hook (Oscillating Hook)

The hook mechanism sits under the bed. This mechanism catches the upper thread loop and wraps it around the bobbin to create a lockstitch.

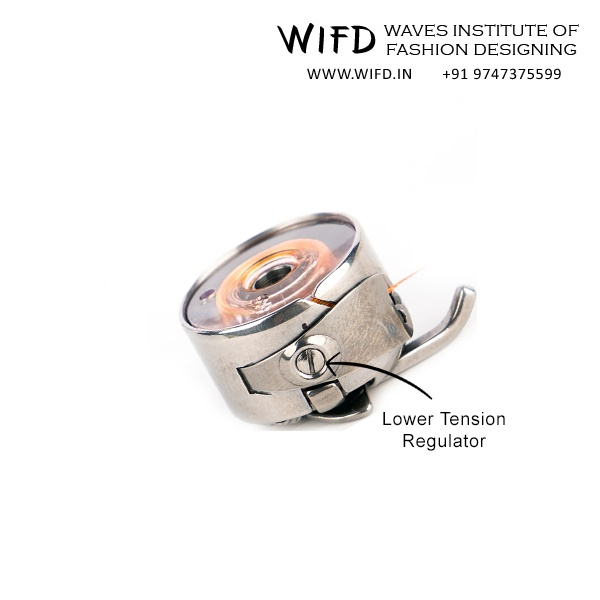

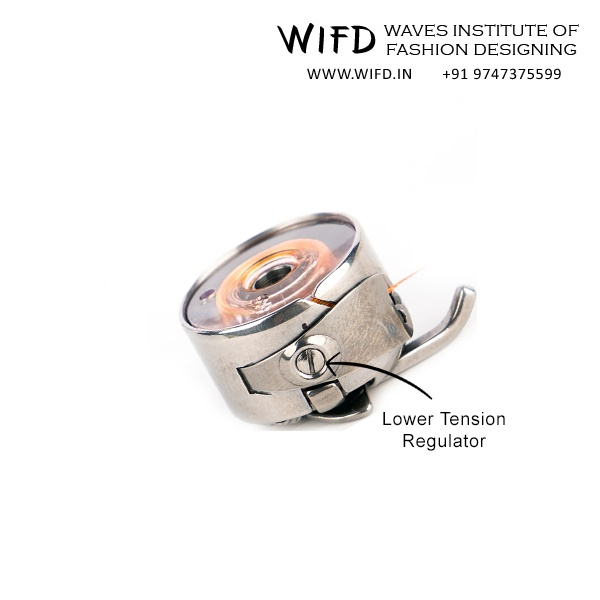

Lower Tension Regulator

This small spring on the bobbin case controls how freely the lower thread releases. To tighten your bobbin tension, slightly turn the tiny screw on the bobbin case clockwise. To loosen bobbin tension, turn the screw anti-clockwise.

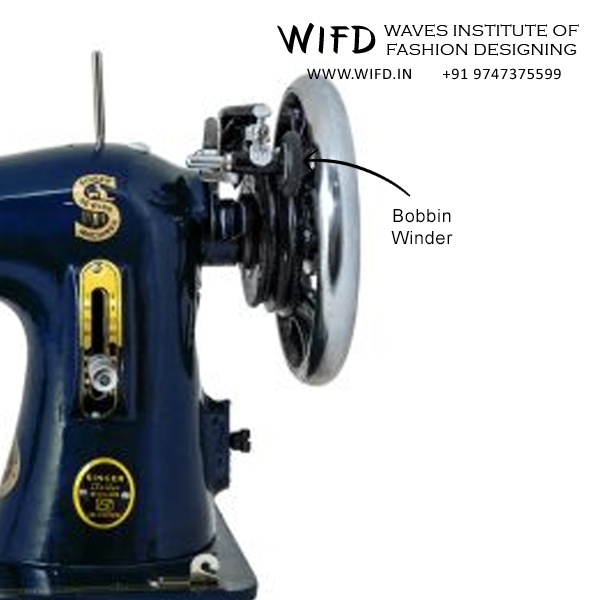

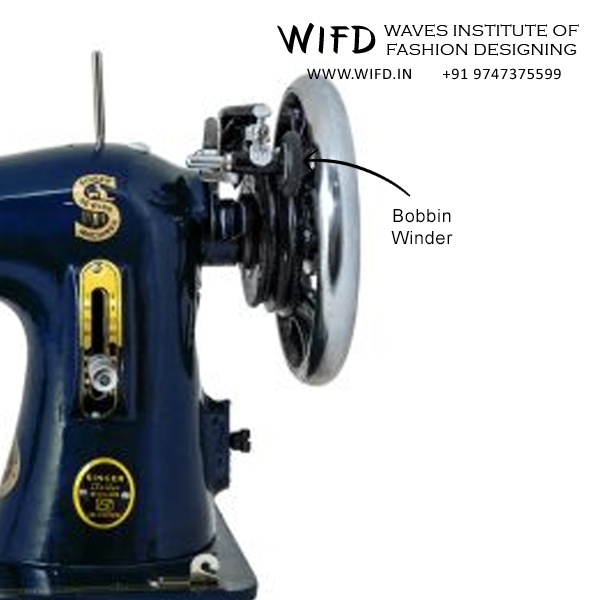

Bobbin Winder

This mechanism winds thread onto empty bobbins. Most machines place it on the right side near the hand wheel. Place an empty bobbin on the winder and guide thread from the spool. Always start with an empty bobbin, to ensure that the thread is uniformly wound.

Stop Motion Screw

This screw sits at the centre of the hand wheel. Loosen it when winding bobbins to disengage the needle while the machine runs.

Rubber Ring

This rubber ring sits on the bobbin winder. It makes contact with the nut of the balance wheel. Keep it clean and dry. Oil causes slipping, so replace the ring if it gets oily.

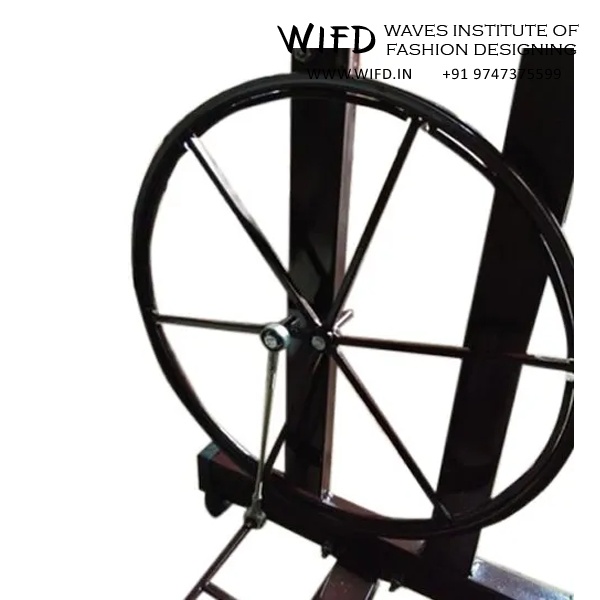

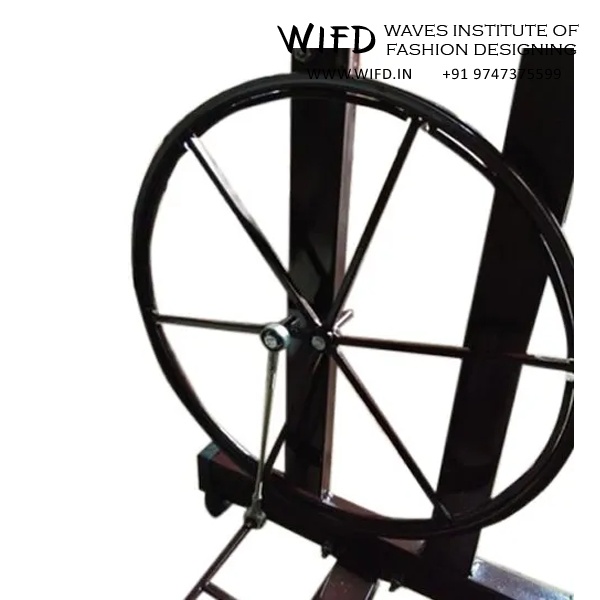

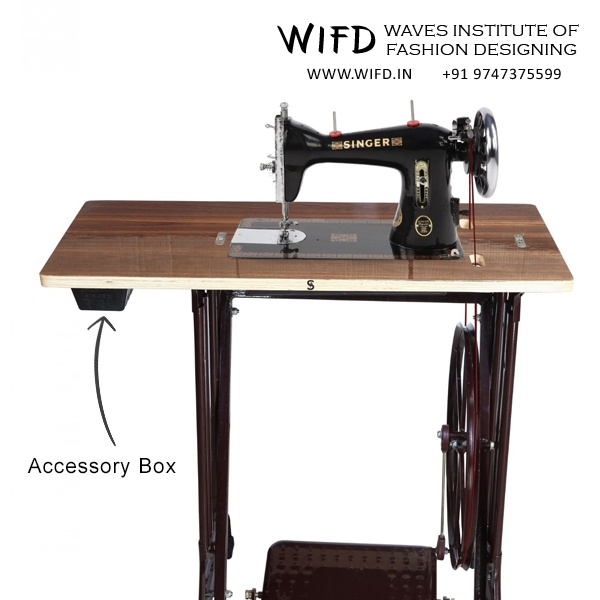

Drive Wheel

This large wheel sits under the machine table. A leather or synthetic belt connects it to the hand wheel and transmits power to operate the machine.

Treadle

In treadle machines, this foot pedal at the base controls stitching speed. Always maintain an even, steady speed throughout your sewing.

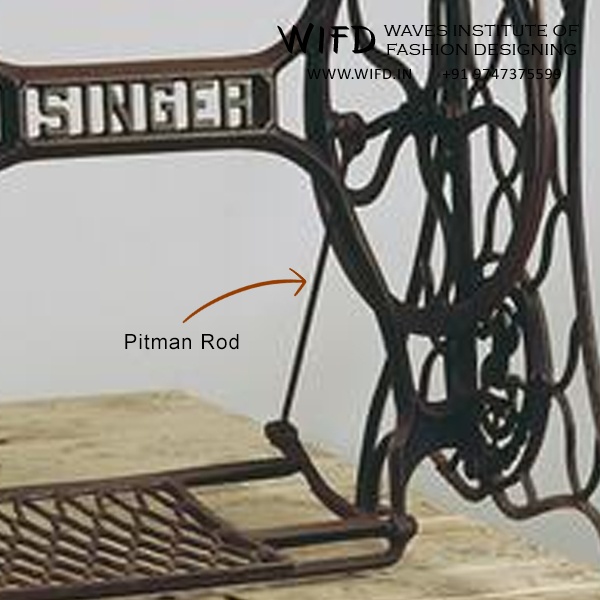

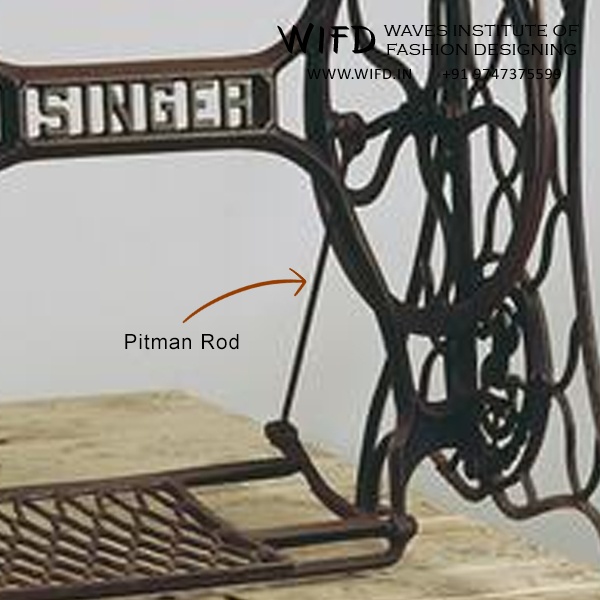

Pitman Rod

This rod connects the treadle to the drive wheel. When you press the treadle, the rod makes the drive wheel turn.

CONTACT USWaves Institute of Fashion Designing,

CONTACT USWaves Institute of Fashion Designing,